A Beginner’s Guide to End Mills: Definition, Types, Structure, Applications, and How to Choose

If you are new to CNC machining or metal cutting, the term “end mill” appears everywhere — in tooling catalogs, CNC programs, and machining discussions. Yet for many beginners, end mills can feel confusing: there are many shapes, coatings, flutes, and specifications.

This article is written for beginners and non-experts. After reading it, you will be able to:

- Understand what an end mill is and what it does

- Identify different types of end mills

- Understand how end mills are categorized

- Know the key elements that define an end mill

- Choose the right end mill for your application

- Confidently recognize and compare end mills on our website

Let’s start from the basics.

What Is an End Mill?

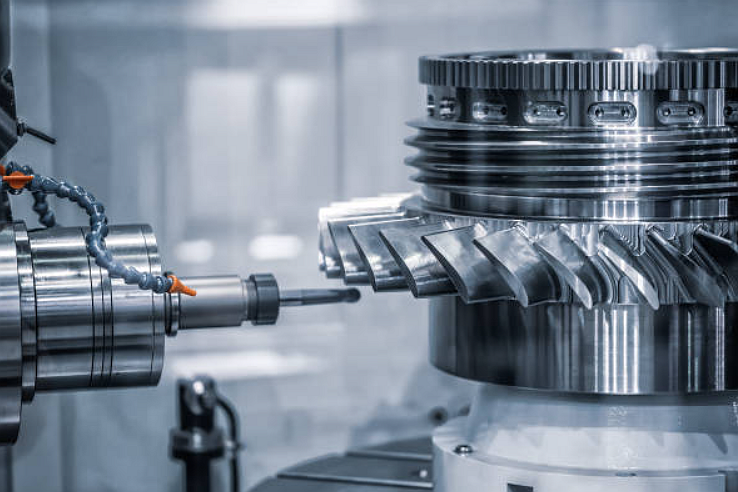

An end mill is a type of rotary cutting tool used in milling machines and CNC machining centers to remove material from a workpiece.

Unlike a drill bit, which can only cut in the axial (downward) direction, an end mill can cut:

- Axially (downward)

- Radially (sideways)

- Diagonally

- Along complex paths

This ability makes end mills extremely versatile. They are used to create:

- Slots and pockets

- Profiles and contours

- Flat surfaces

- 3D shapes and cavities

In simple terms:

A drill makes holes. An end mill shapes parts.

What Materials Are End Mills Used On?

End mills are used to machine a wide range of materials, including:

- Carbon steel and alloy steel

- Stainless steel

- Aluminum and aluminum alloys

- Cast iron

- Titanium and superalloys

- Plastics and composites

Different materials require different end mill designs, which is why there are many types available.

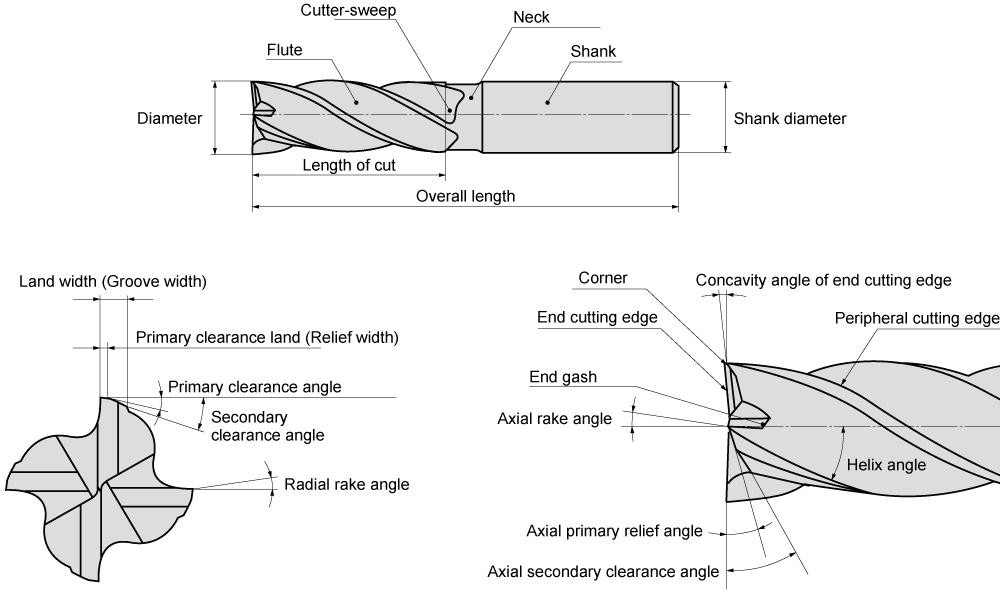

Basic Structure of an End Mill

To understand and identify an end mill, you must first understand its structure. take a look at the below image.

Main Parts of an End Mill

- Shank

- The part held by the tool holder or collet

- Usually cylindrical

- Common standards: straight shank, Weldon shank

- Cutting Diameter

- The diameter of the cutting part

- Determines slot width and machining size

- Flutes

- Spiral grooves along the cutting length

- Responsible for cutting and chip evacuation

- Cutting Edge

- Sharp edges along the flutes that actually remove material

- End Teeth (Bottom Edge)

- Cutting edges at the tool tip

- Enable plunging and bottom cutting

- Neck (if applicable)

- Reduced diameter between shank and cutting part

- Used for deep cavities or long reach

Understanding these parts makes it much easier to read end-mill specifications.

How Are End Mills Categorized?

End mills can be categorized in several ways. On professional websites, you will usually see multiple classification methods used together.

4.1 By End Shape (Most Common)

Square End Mill

- Flat bottom

- Sharp corners

- Used for slotting, side milling, and general machining

Ball Nose End Mill

- Rounded tip

- Used for 3D contouring, molds, dies, and curved surfaces

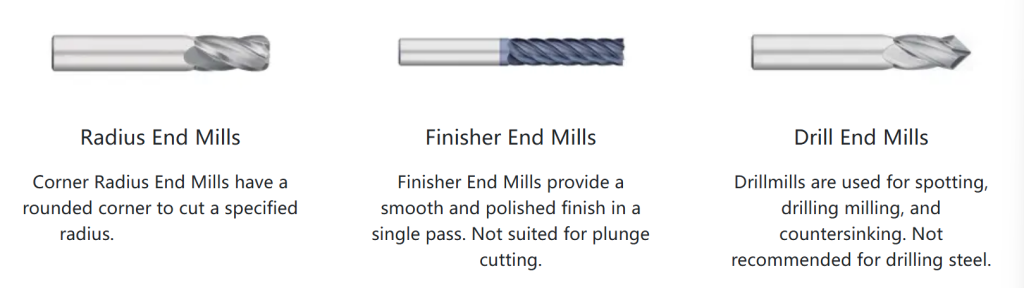

Corner Radius End Mill

- Small radius at the corner

- Stronger than square end mills

- Reduces chipping and improves tool life

4.2 By Number of Flutes

The number of flutes affects chip removal and surface finish.

2-Flute End Mill

- Large chip space

- Best for aluminum and soft materials

3-Flute End Mill

- Balance between strength and chip evacuation

- Very popular for aluminum machining

4-Flute End Mill

- Strong cutting edges

- Suitable for steel and harder materials

Variable Flute End Mill

- Uneven flute spacing

- Reduces vibration and chatter

- Used for high-performance machining

4.3 By Material of the Tool

Solid Carbide End Mills

- Most common in modern CNC machining

- High hardness and wear resistance

- Suitable for high speeds and precision work

HSS (High-Speed Steel) End Mills

- Lower cost

- More flexible

- Used for manual machining or softer materials

4.4 By Coating

Coatings improve tool life and cutting performance.

Common coatings include:

- Uncoated – good for aluminum and plastics

- TiN – general wear resistance

- TiAlN / AlTiN – high-temperature resistance, steel machining

- AlCrN – heavy cutting and hard materials

- DLC – aluminum and non-ferrous materials

Coating selection depends on material and cutting conditions.

4.5 By Application

Many end mills are designed for specific uses:

- Aluminum-specific end mills

- Steel-specific end mills

- Stainless-steel end mills

- Roughing end mills (for heavy material removal)

- Finishing end mills (for surface quality)

This is why product categories on a website often include material-based groupings.

Key Elements You Must Understand About an End Mill

When choosing or identifying an end mill, focus on these key parameters.

5.1 Diameter

- Determines cutting width

- Must match design dimensions

5.2 Cutting Length (LOC)

- Length of the fluted cutting area

- Important for pocket depth and side milling

5.3 Overall Length (OAL)

- Total tool length

- Affects rigidity and reach

5.4 Helix Angle

- Angle of the flutes

- Higher helix = smoother cutting, better surface finish

5.5 Tolerance

- Diameter accuracy (e.g., h6, h5)

- Important for precision machining

Understanding these parameters allows you to compare tools accurately on our website.

Common End Mill Applications

End mills are used in almost every machining industry.

General Machining

- Slotting

- Facing

- Side milling

Mold & Die

- 3D cavity machining

- Finishing curved surfaces

Aerospace

- Aluminum structural parts

- Titanium components

Automotive

- Engine components

- Fixtures and tooling

Medical

- Precision parts

- Small-diameter milling

Each application demands different end-mill designs.

How to Choose the Right End Mill (Beginner’s Method)

If you are new, follow this simple step-by-step approach.

Step 1: Identify the Workpiece Material

- Aluminum → fewer flutes, polished flutes

- Steel → more flutes, strong coating

- Stainless steel → sharp edges, vibration control

Step 2: Choose the End Shape

- Flat surfaces → square end mill

- 3D contours → ball nose

- Longer tool life → corner radius

Step 3: Select Flute Count

- Soft material → 2–3 flutes

- Hard material → 4 or more flutes

Step 4: Check Length Requirements

- Shallow cutting → standard length

- Deep pockets → long or necked end mills

Step 5: Match Coating to Application

- Aluminum → uncoated or DLC

- Steel → TiAlN / AlCrN

This process works for most beginners.

How to Identify End Mills on Our Website

When browsing our product pages, you will see:

- End-mill type (square, ball nose, corner radius)

- Diameter and length options

- Number of flutes

- Recommended materials

- Coating information

By using the knowledge from this article, you can:

- Understand product differences quickly

- Choose suitable tools without confusion

- Compare multiple end mills effectively

Common Beginner Mistakes

Avoid these common errors:

- Using too many flutes for aluminum

- Choosing long tools when short tools are sufficient

- Ignoring coating recommendations

- Selecting tools based only on price

Correct selection improves both tool life and machining quality.

Final Thoughts

End mills are the core cutting tools in modern CNC machining. While they may look similar at first glance, small differences in geometry, flute count, and coating make a big difference in performance.

By understanding:

- What an end mill is

- How it is structured

- How it is categorized

- How to choose the right one

you are now equipped to confidently select and identify end mills for your machining needs.

If you need assistance choosing the right end mill for your application, our technical team is always ready to help.