Product Description:

The tool is used for the processing of frames and shells such as computer hard disk ,mobile phones,and the processing of some non-ferrous material such as aluminum,magnesium,chin,silicon,etc. as well as the processing of some non-metallic materials ,such as fibermaterials ,insulating materials,plastics,composite materials,etc.

Advantages

a.Ultrafine crystal grains, mirror processing effect, long service life.

b.Surface finish less than 0.4u, mirror effect and very shinning.

c.Wear-resistant and very long work life, much more than carbide materials.

d.Four times of cutting tool detection to ensure the quality

Feature:

a.Suitable for non-ferrous metal materials,non-metal materials,and composite materials.

b.Can get a faster cut cutting speed and longer tool life, get high surface quality and accuracy.

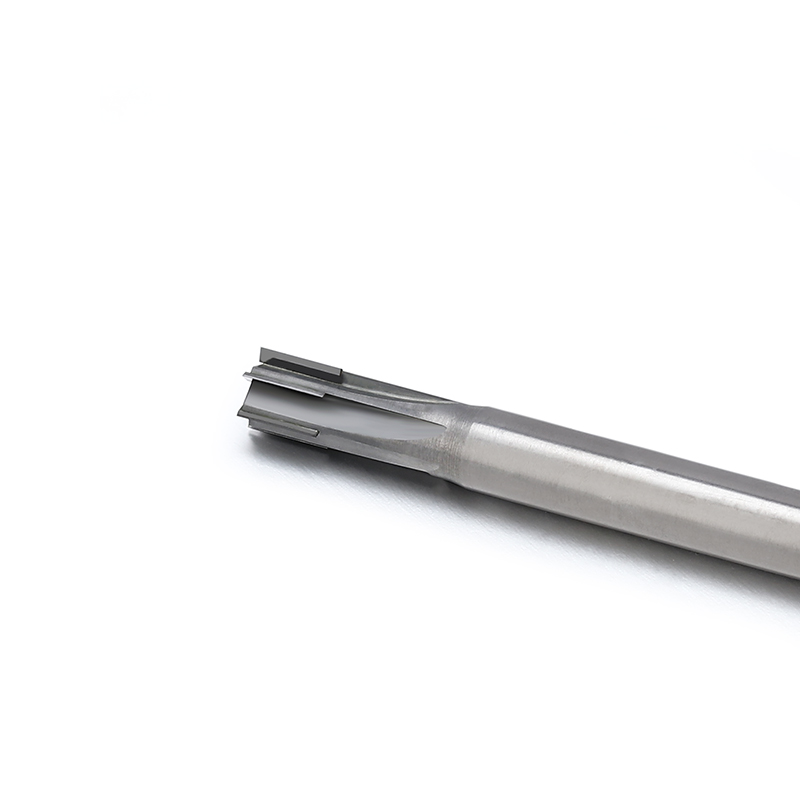

Design:

a.Circumferential edge band and passivation, improve the tool life and stability of the cutting process.

b.PCD corner radius end mill cutter is a arc-shaped design, can efficiently process narrow areas or curved surfaces.

c.PCD ball nose end mill cutter is a reasonable new type of structural tool for machining complex curved surfaces on CNC machine tools. It’s one of the important tools used in complex 3D surface finishing,it’s for complest spatial surface.

| 1.Double core diameter design ideal.:strong strength for plunge and pocket milling ideal using on stainless steel 1. 理想的双芯直径设计:适合不锈钢的深入和口袋铣削,强度强a.The small core diameter of the front end can ensure the chip removal smooth ,take away the heat of cutting production, and prevent the production of built-up edge 答:前端小芯径可确保切屑平滑,减少切割产生的热量,并防止边缘形成b.The big core diameter at the back end ehance the rigidity of cutting tools and improve the surface quality of products b. 后端的大芯径增强了切削工具的刚性,并提升了产品的表面质量 |

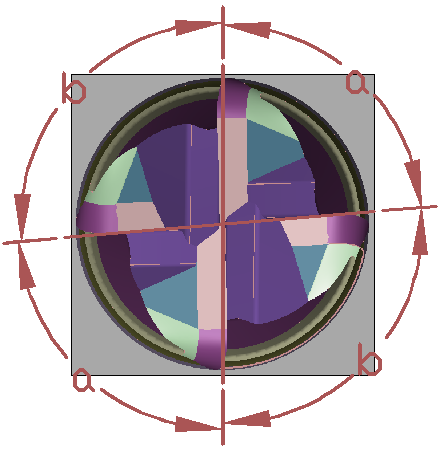

| 2.a≠b Unequal design:prevents vibration and reduces cutting force at slotting. This has led to the high speed and high feed machining 2.a≠b 不等设计:防止振动并降低开槽切削力。这促成了高速和大进给加工 |

| 3.Variable helix to prevent vibration 3. 可变螺旋防止振动Special variable pitch profile reduces cutting force and stress on machine spindle 特殊的可变铣刀轮廓可降低切削力和机床主轴的应力 |