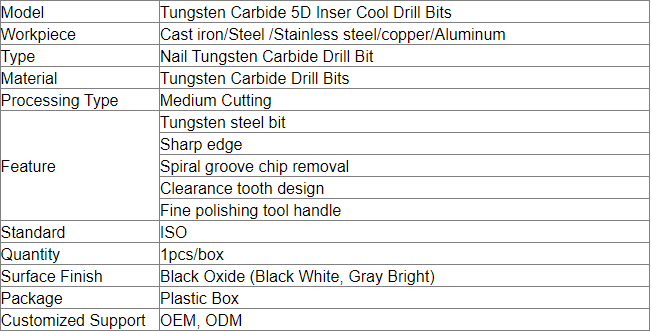

Description:

New fine particle tungsten steel base material, high hardness and wear resistance; The clearance gear is designed to locate the drilling position, enhance the stability and seismic resistance of the tool, and greatly reduce the probability of tool breakage; The spiral edge is polished, with high hardness, strong shock resistance, and will not jump. With spiral groove chip removal, the chip removal is smooth and not easy to block the knife; The unique chamfer design of the handle end is easy to install and close to the collet, and the clamping is tighter without slipping, while increasing the stability of drilling.

Parameter:

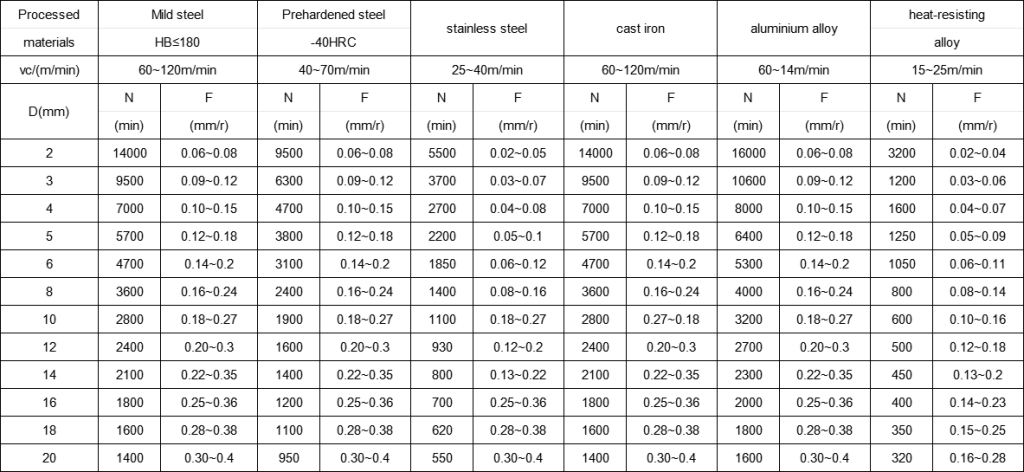

3D/5D External Cooling Cutting Parameters

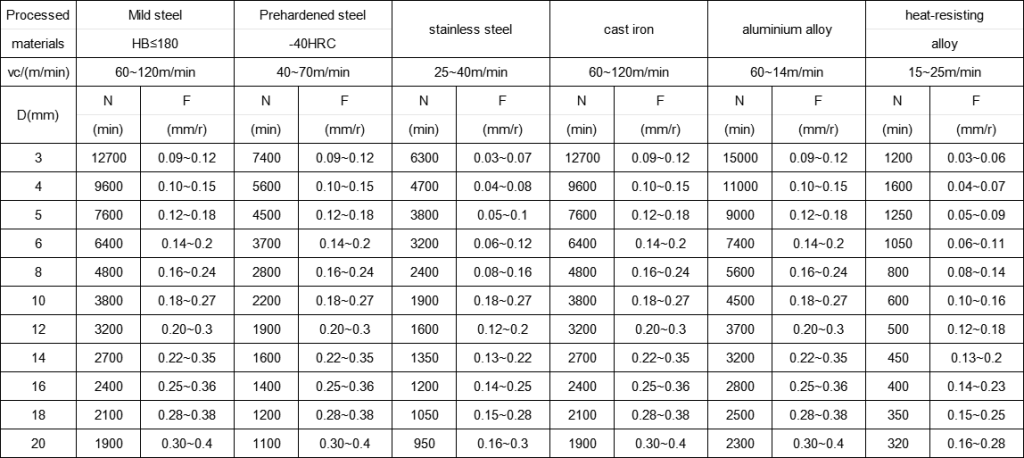

3D/5D internal cooling cutting parameter

- When using this tungsten carbide drill bits for the first time, try to cut at 90% of the cutting speed or 85% of the feed speed according to the above data, and then increase the cutting speed and feed rate one by one after the cutting condition is stable

- This standard cutting condition is applicable to water-soluble cutting fluid

- When installing the tool, please use a clean chuck with defects removed, and control the radial runout of the drill bit within 0.02mm

- The cutting conditions in this table are applicable to situations with hole depth below 5D

Notice:

- When drilling steel parts, please ensure sufficient cooling capacity and use metal cutting fluid.

- Good drill pipe rigidity and guide rail clearance can improve drilling accuracy and bit life.

- Please ensure the flatness and cleanness between the magnetic base and the workpiece.

- When drilling thin plates, reinforce the workpieces. When drilling large workpieces, ensure that the workpieces are stable.

- At the beginning and end of drilling, the feed rate shall be reduced by 1/3.

- For materials with large amount of fine powder during drilling, such as cast iron, cast copper, etc., compressed air can be used instead of coolant to help remove chips.

- Please remove the iron scraps wrapped on the drill body in time to ensure smooth chip removal.

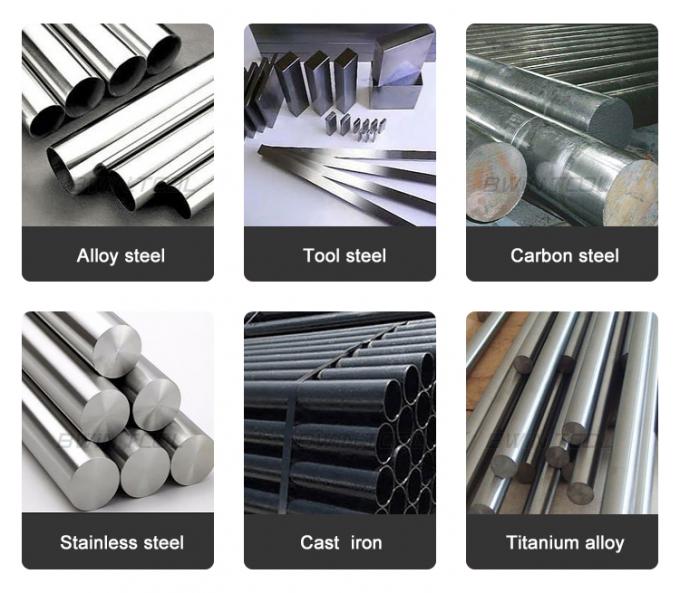

Applications:

Our tungsten carbide drill bits could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following: