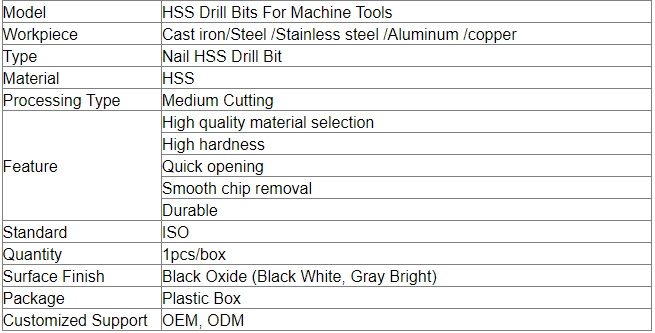

Description:

- The whole 4341 high speed steel is forged, with higher hardness and durability

- CNC fine grinding 118 ° double rear corners, sharper cutting and faster drilling speed

- Widen chip discharge groove, with efficient chip discharge speed, effectively preventing blade burning caused by accumulated temperature

- Universal shank for tighter clamping

Specifications:

Parameter:

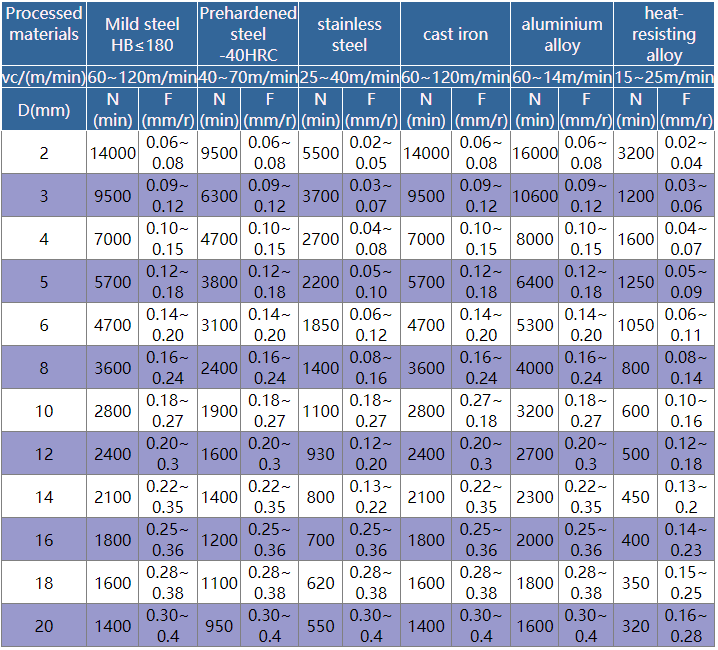

3D/5D External Cooling Cutting Parameters

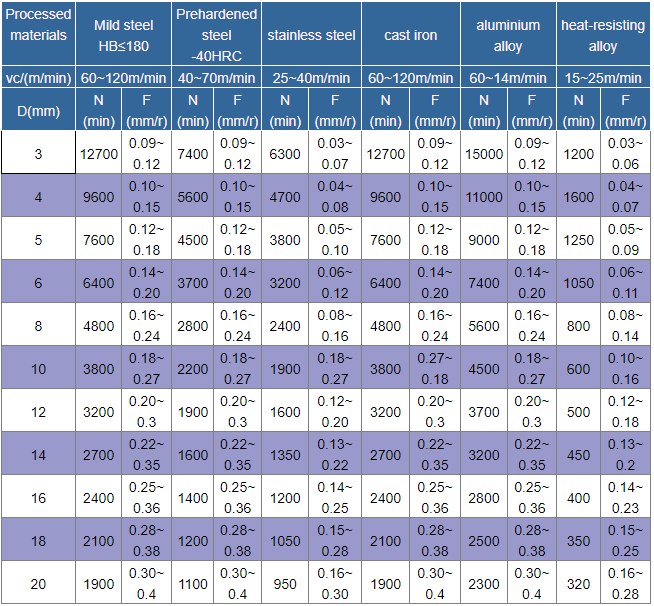

3D/5D internal cooling cutting parameter

- When using this HSS drill bits for the first time, try to cut at 90% of the cutting speed or 85% of the feed speed according to the above data, and then increase the cutting speed and feed rate one by one after the cutting condition is stable

- This standard cutting condition is applicable to water-soluble cutting fluid

- When installing the tool, please use a clean chuck with defects removed, and control the radial runout of the drill bit within 0.02mm

- The cutting conditions in this table are applicable to situations with hole depth below 5D

Notice:

- When drilling steel parts, please ensure sufficient cooling capacity and use metal cutting fluid.

- Good drill pipe rigidity and guide rail clearance can improve drilling accuracy and bit life.

- Please ensure the flatness and cleanness between the magnetic base and the workpiece.

- When drilling thin plates, reinforce the workpieces. When drilling large workpieces, ensure that the workpieces are stable.

- At the beginning and end of drilling, the feed rate shall be reduced by 1/3.

- For materials with large amount of fine powder during drilling, such as cast iron, cast copper, etc., compressed air can be used instead of coolant to help remove chips.

- Please remove the iron scraps wrapped on the drill body in time to ensure smooth chip removal.

Applications:

Our HSS drill bits could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following: