Description:

1.The raw material of tungsten steel from large state-owned enterprises is preferred. The milling cutter has a series of excellent characteristics such as higher hardness, stronger wear resistance, high temperature resistance, corrosion resistance, etc

2.Balchas nano composite coating enhances the rigidity of the tool, increases the wear resistance of the carbide corner radius end mill, reduces the number of tool changes, and extends the service life

3.Full grinding edge double edge belt design, compatible with the edge strength and sharpness, no burr on the edge, not easy to break, and improve the milling efficiency

4.Large core diameter design, fine grinding spiral groove, smooth chip removal, avoiding knife sticking, greatly improving production efficiency

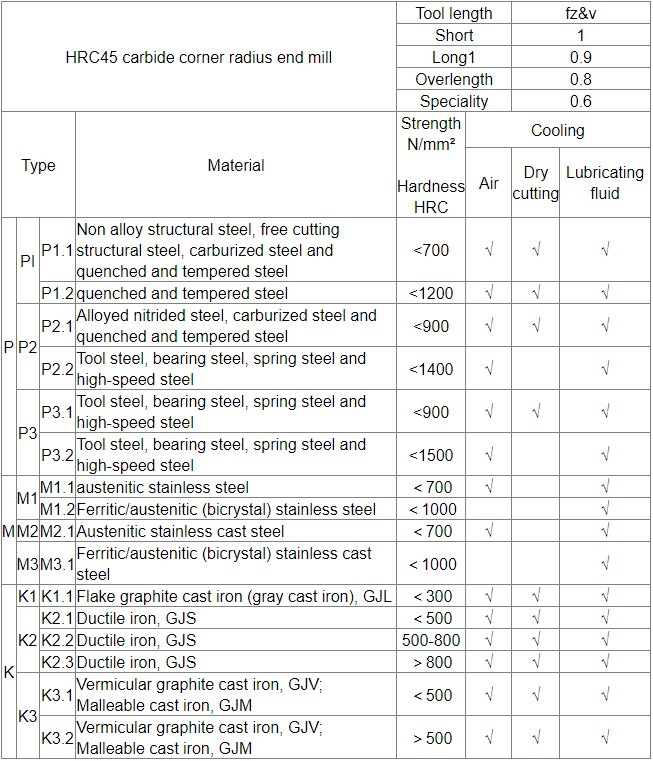

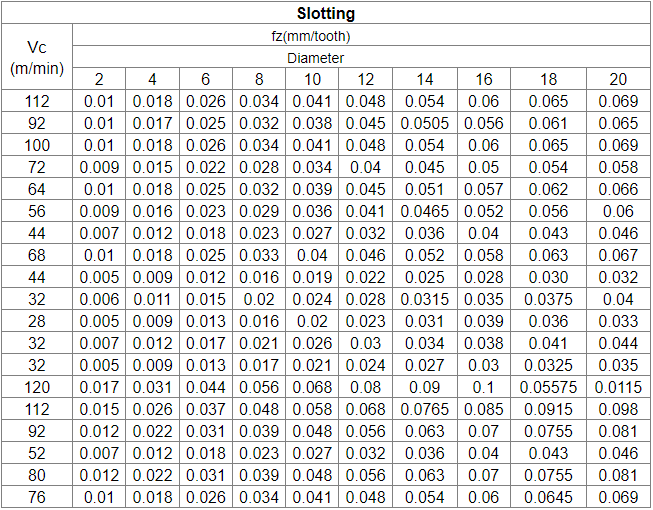

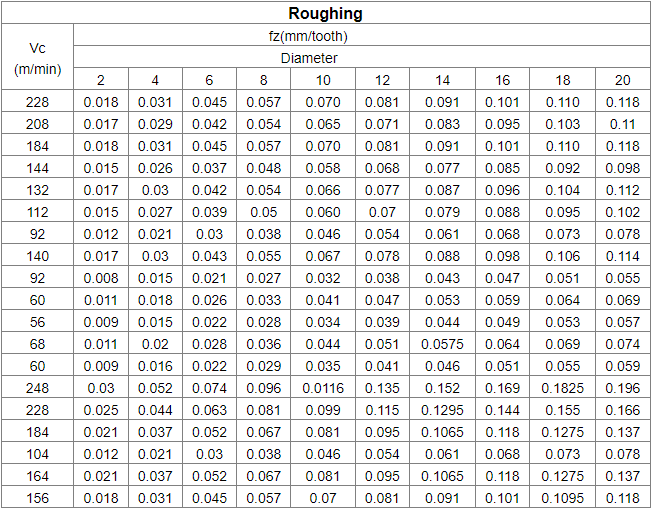

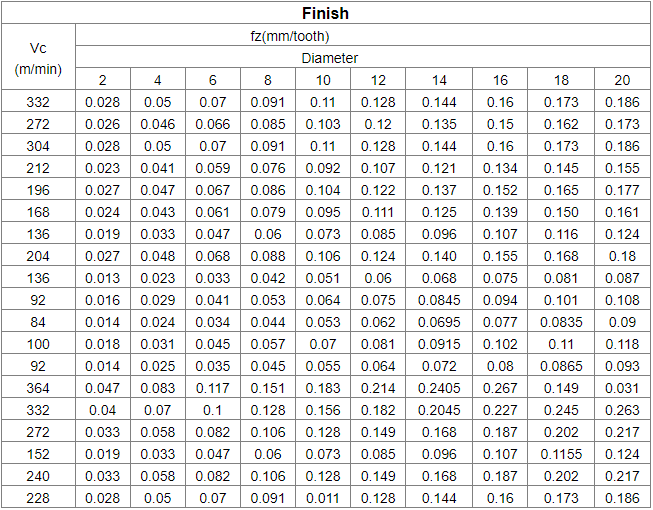

Milling Parameters:

Note:

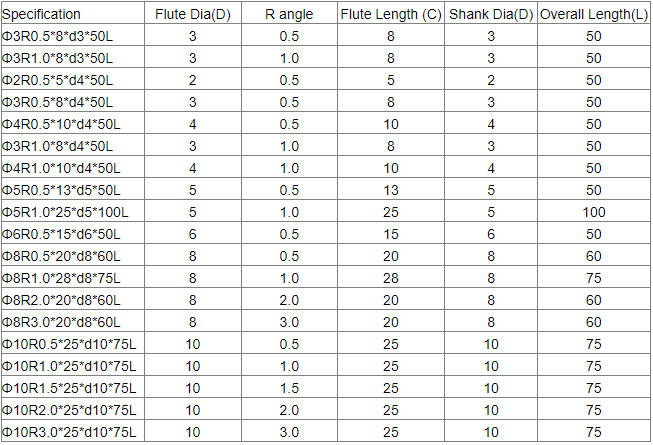

If the following carbide corner radius end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter.

Instructions:

- Before using the carbide corner radius end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

- The shorter the carbide e extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

- In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

- Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide end mill.

- Note: Not suitable for low speed machines such as rotary table and electric hand drill.

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.