Description:

The flat end mill is made of ultra-fine tungsten steel with high wear resistance and strength. The coating has stable performance and can be used in high temperature environment without easy wear; The unique design of knife edge fine grinding, large chip discharge groove and large spiral chip discharge groove make the cutting and chip discharge more smooth, with good surface finish and sharp cutting. Modern grinding machines are equipped with high-precision grinding tools. No slight defects are found at the full grinding edge, and the iron is cut into mud; High temperature resistance, oxygen resistance, long service life, is the best choice for the application of high hardness and high-speed cutting.

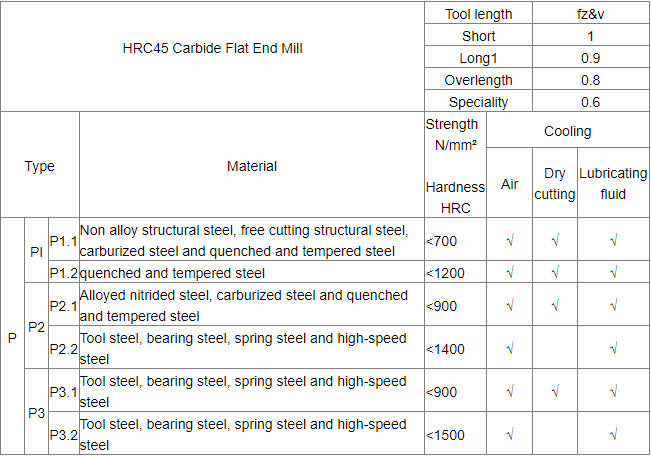

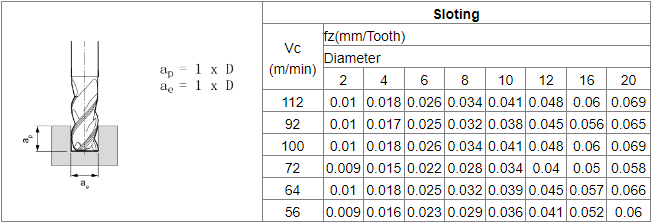

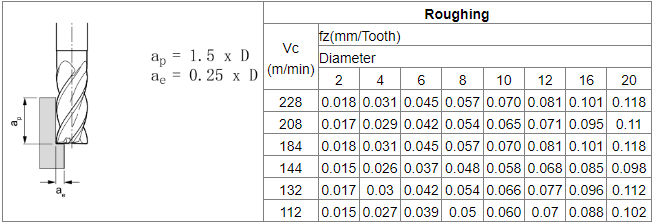

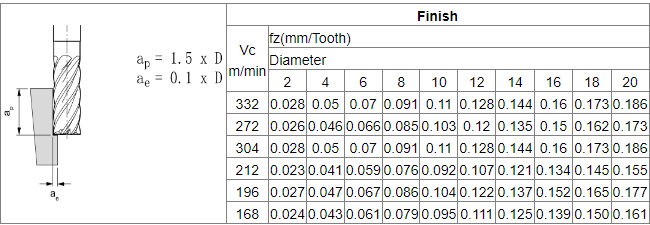

Milling parameters:

Note:

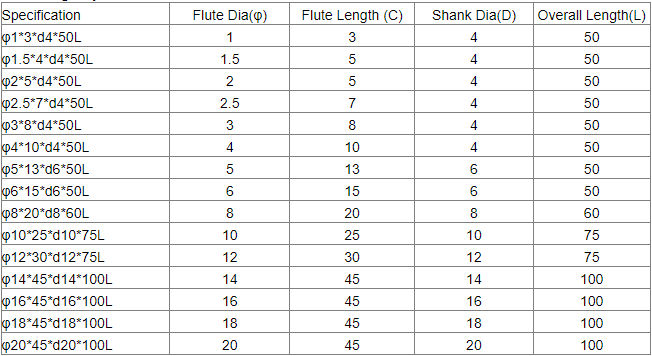

If the following carbide flat end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

Notice:

- Please use equipment and fixtures with good rigidity and high precision.

- Please select the cutting fluid applicable to the workpiece material.

- During high-speed machining, avoid using cutting fluid with strong flammability.

- When the used equipment cannot increase the speed, please reduce the feed speed and speed by the same proportion.

- When clamping the flat end mill, please control the runout of the blade tip within 0.01mm.

Reminder:

The coating color will vary with the manufacturing batch, but the quality and performance will not be affected, so you can use it with confidence.

As the coating is non-conductive, please do not use conductive tool setting instrument.

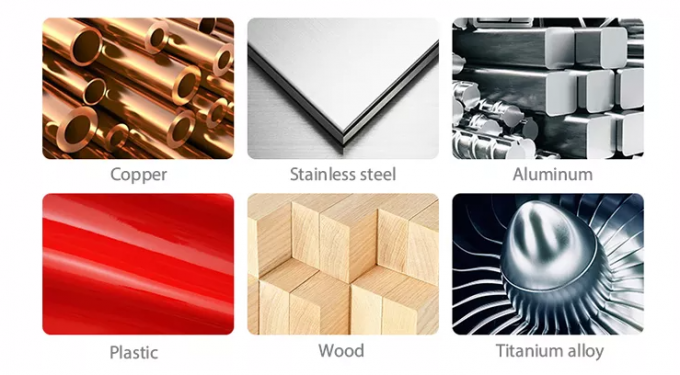

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.