Description OF inner-R Aluminum End Mill

The HRC55 4-blade aluminum internal R milling cutter is carefully ground with excellent tungsten steel raw materials, which has high wear resistance and strength; Adopting a suitable blade design that takes into account both the strength and sharpness of the blade, while also adopting a large core diameter to enhance the rigidity of the tool and ensure stable cutting and chip removal; Large capacity chip removal has strong cutting ability, smooth chip discharge, and can achieve high efficiency machining; The full edge seismic design can suppress chatter during the machining process and improve the quality of the machined surface.

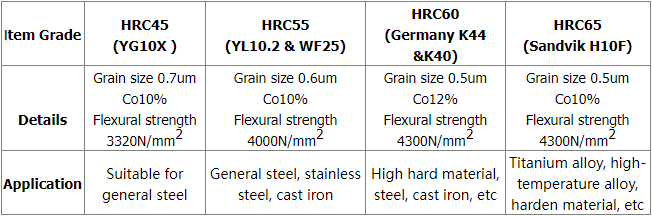

Carbide material introdution

Note OF inner-R Milling Cutter

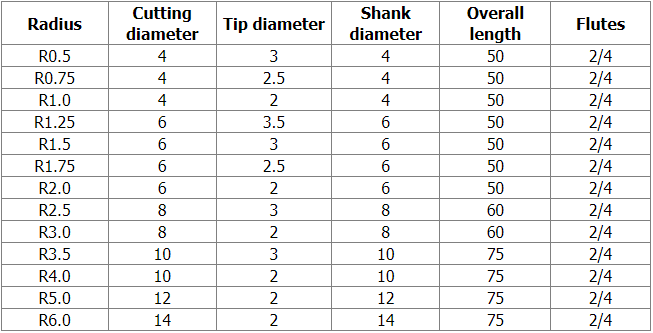

If the following carbide internal R milling cutter cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

Instructions OF internal R Milling Cutter

- Before using the carbide internal R milling cutter, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

- The shorter the carbide e extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

- In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

- Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide inner R milling cutter.

- Note: Not suitable for low speed machines such as rotary table and electric hand drill.

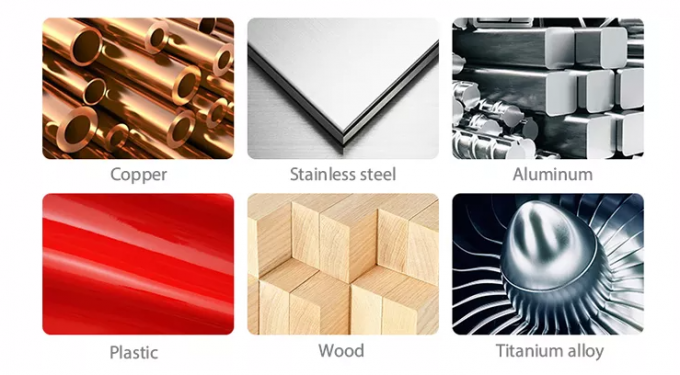

Applications OF internal R End Mill