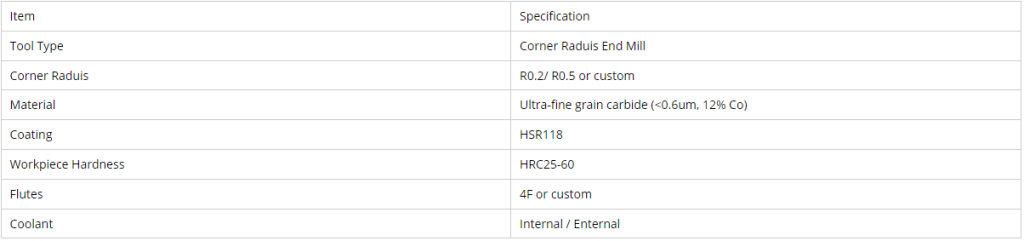

workpiece material:Steel、Stainless Steel、Cast Iron、Nonferrous materials、Titanium alloy

Application type:Dynamic Milling 、Roughing

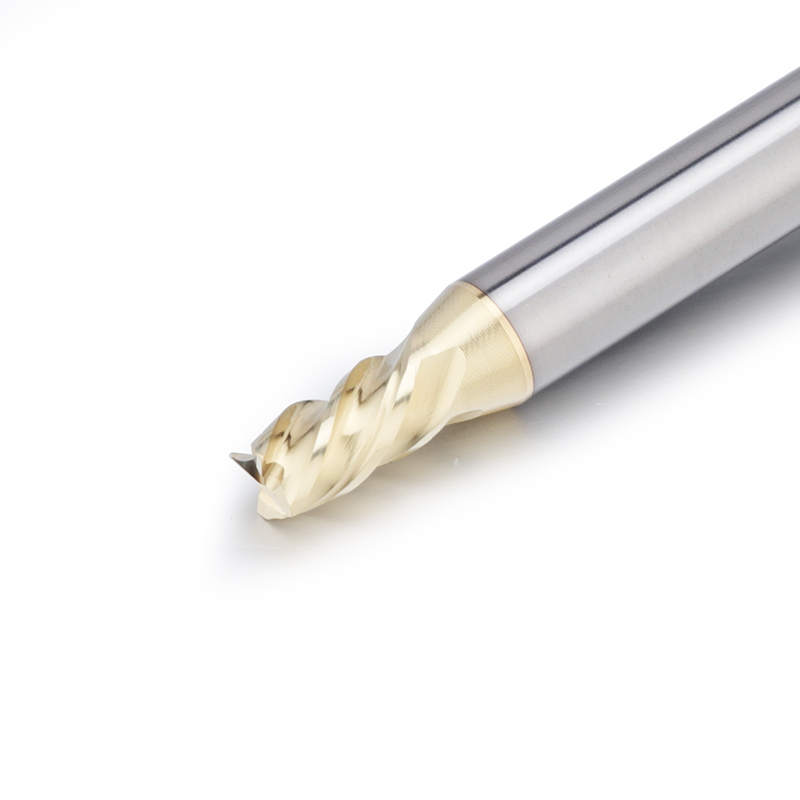

Flute type:Corner radius

Coating:HSR118 comparable to JZR coating

Introduction:

Dohre DEX Series corner radius end mill is specially engineered for stable, high-efficiency machining of titanium alloys and difficult cutting materials.

With a reinforced corner radius design, advanced coating technology, and optimized flute geometry, DEX delivers longer tool life, reduced vibration, and superior performance in high-load roughing and dynamic milling applications.

Product Description

Application Range

The DEX corner radius end mill is suitable for machining materials with hardness HRC 25–60, including:

•Titanium alloys

•Aluminum-titanium alloys

•Stainless steel

•Alloy steel & carbon steel

•Mold steel

•Cast iron

•Non-ferrous metals