Description of thread milling cutter

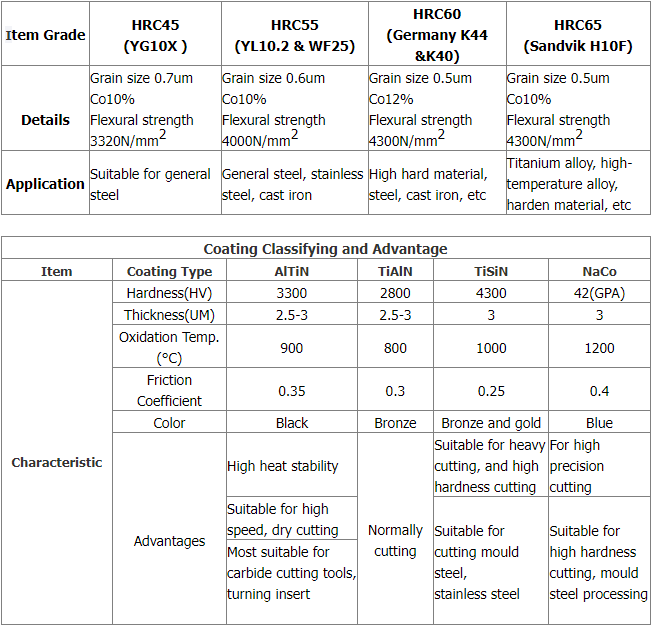

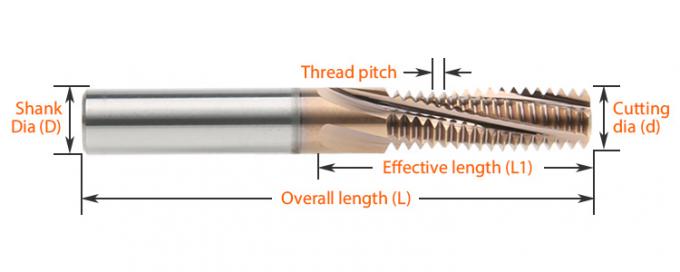

The ultrafine particle alloy matrix is equipped with a Balchals coating, and the HRC55 full tooth thread milling cutter has excellent toughness and high temperature resistance, with low chemical affinity; Adopting an excellent new blade shape with a smooth surface that is not prone to chipping, enhancing the rigidity of the tool, taking into account both the tool’s rigidity and chip removal performance, making the cutting and chip removal of the tool more stable; The design of inclined multiple chip removal slots is conducive to chip removal, spiral heat dissipation, efficient tooth milling, smooth chip removal, larger capacity, and smooth without burrs; Smooth and smooth handle with precise chamfering, saving tool replacement time and improving processing efficiency.

Milling parameters OF Sprial End Mill

Note OF Helix End Mill

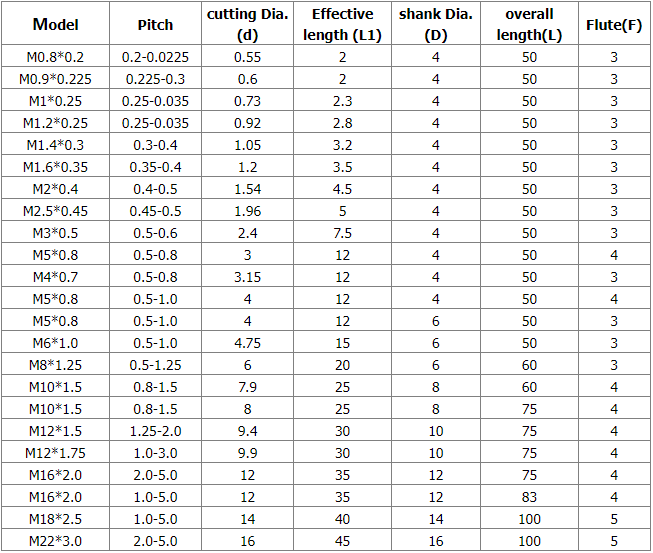

If the following carbide thread milling cutter cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

Instructions OF Helix End Mill

- Before using the carbide Thread milling cutter, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

- The shorter the carbide extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

- In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

- Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide Thread milling cutter.

- Note: Not suitable for low speed machines such as rotary table and electric hand drill.

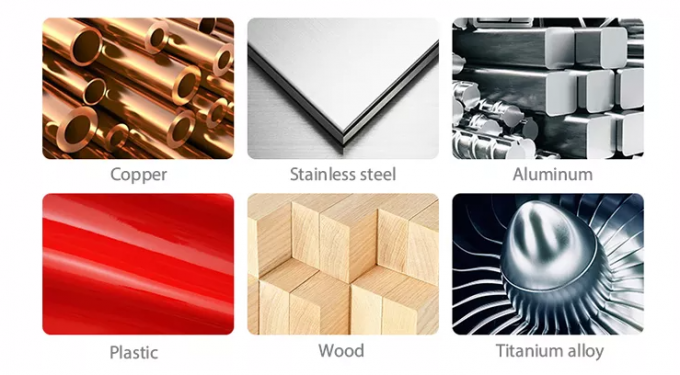

Applications OF Thread End Mill

The cutting edge of the HRC55 micro diameter square aluminum end mill is covered with a bronze colored nano coating, suitable for materials within HRC55, including Stainless steel, mold steel, tool steel, pre hardened steel, quenched parts, titanium alloys, high-temperature alloys, cast iron materials, etc. Suitable for drilling and attacking integrated table drills, precision carving machines, automatic machine tools, CNC machining centers.