Description:

The flat end milling cutter head adopts advanced coating technology to create a balanced paint surface, which is rust proof, high temperature resistant and beautiful; The proper negative rake angle design is adopted to strengthen the strength and sharpness of the cutting edge. At the same time, the large core diameter design is adopted to enhance the rigidity of the tool, so that its cutting performance and chip removal performance tend to be stable; The circular arc edge band edge cleaning design is adopted, so that the milling cutter is less worn during milling, and the blade is permanently sharp. With the 35 ° spiral groove, the chip can be discharged smoothly without chip accumulation.

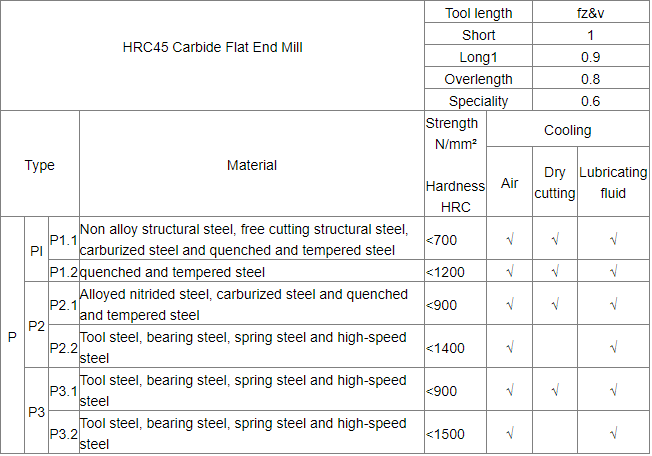

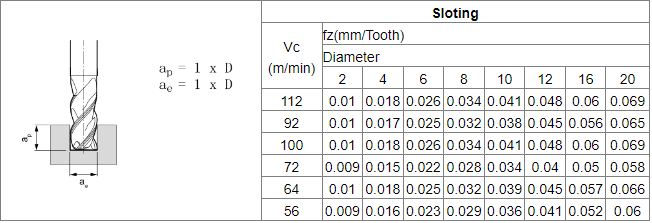

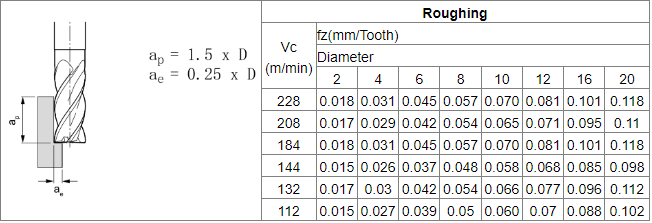

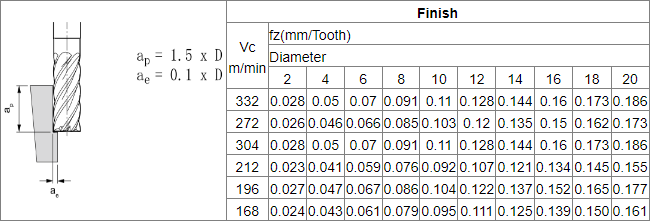

Milling parameters:

Note:

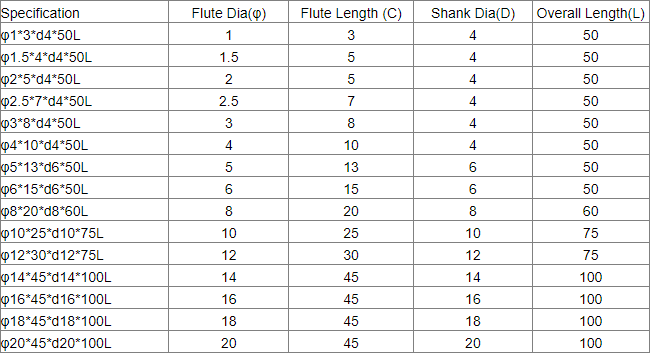

If the following carbide flat end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter.

Notice:

- Before using the tool, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

- The shorter the tool extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

- In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

- Spray type and air jet type are preferred for steel cooling, which can improve the use effect of milling cutter.

- Note: Not suitable for low speed machines such as rotary table and electric hand drill

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.