Description:

The ball end milling cutter made of ultra-fine particle tungsten steel base material is preferred, which has high wear resistance and strength; High precision grinding technology of imported Walter grinder, not easy to wear, long service life; The five axis grinding machine imported from Germany is used to fully grind the cutting edge, and the tool surface has a mirror effect to improve the surface finish; The chip removal groove is designed to ensure smooth chip removal during processing, which can effectively reduce product cracks and wear. The unique spiral edge angle makes the cutting sharp, wear-resistant and smooth, greatly improving the cutting efficiency.

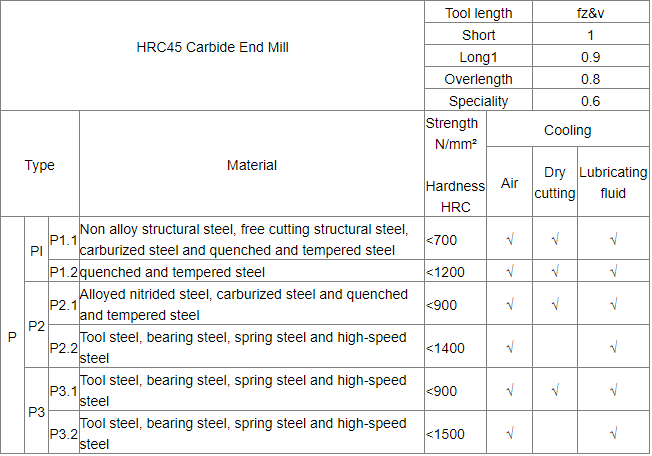

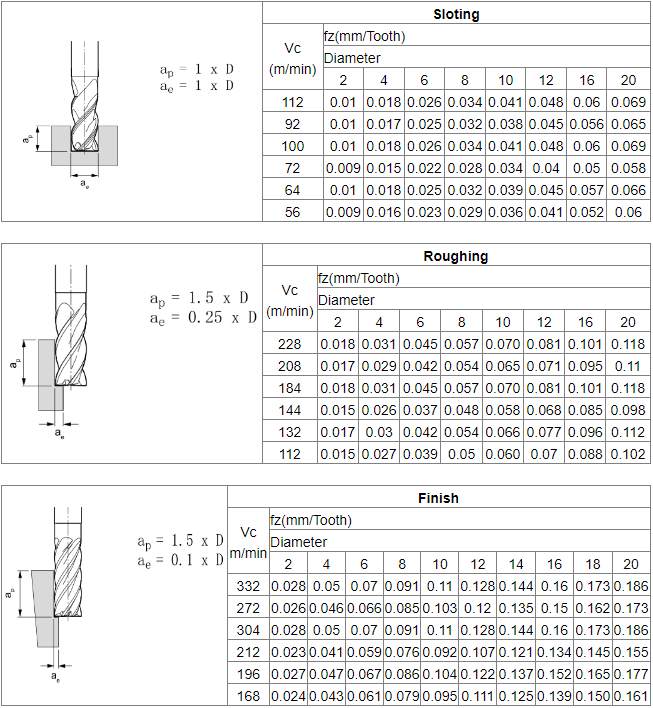

Milling parameters:

Note:

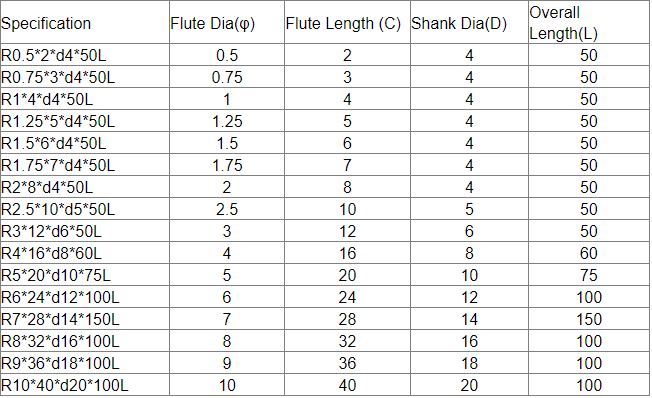

If the following carbide end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter.

Notice:

1.Minimize the use of tool tips to process workpieces: At the position of the ball head tool tip, the processing linear speed is 0 during actual processing, that is, the tool is not actually cutting, but grinding. In actual processing, the coolant can not be added to the cutting area at all, which further leads to greater cutting heat ratio and reduced tool life.

2.For straight wall processing, use contour contour processing method: Try to reduce the phenomenon of ball end cutter processing downward along the straight wall. Relatively speaking, it is a very good method to process upward along the straight wall, but it is difficult to separate them in actual processing. Let’s compare the differences between the two.

3.Machining straight wall with contour can reduce downward machining. If you can use “cutting from bottom to top”, this phenomenon can be avoided. When using “cutting from bottom to top”, first consider whether the cutting capacity of the cutter is too large. If there are relatively large residues left at the root of the curved surface after machining above, the cutting capacity of the cutter may be too large. This will not protect the tool but destroy it.

4.The ball end milling cutter shall pay attention to the processing of deep grooves: When processing deep grooves, the cutter may sink. Because the chip holding groove of the ball end milling cutter is relatively small, it is easy to break the cutter when processing sticky materials (such as red copper) and the feed speed is fast. Therefore, pay attention to chip removal when using ball end cutter for machining.

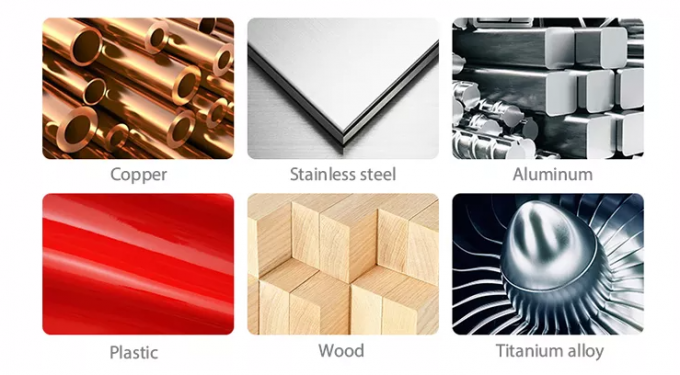

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.