Product Details of carbide drill bits

- Blade installation position: Easy replacement and low cost after blade wear

- Internal cooling water outlet hole: fully utilize the cutting function of the drill bit to ensure machining reliability

- Widening the chip removal slot: effectively avoiding chip accumulation and improving service life

- Overall grinding: Appearance grinding, overall nickel plating, rust prevention

- Internal cooling water outlet: With screw teeth inside, it is easy to install and can be used on a lathe

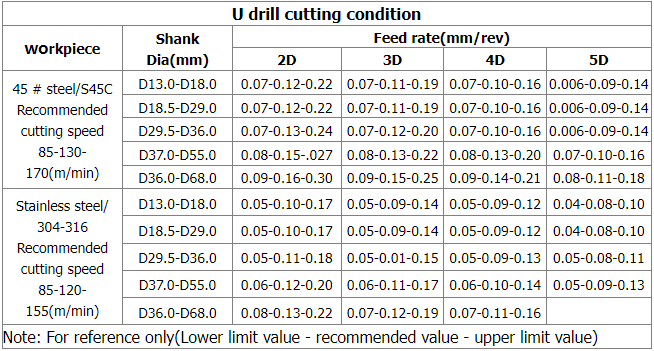

U-drill cutting condition table

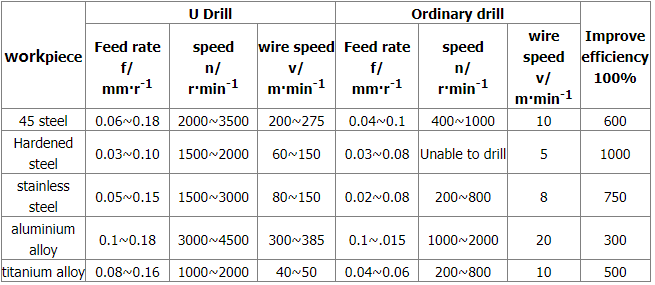

Comparison of cutting parameters between U-drill and ordinary drill bits

- In the initial drilling, it is recommended to use the cutting value in the middle range, and then adjust the cutting parameters (according to the tool wear) to achieve the best cutting effect. The above cutting parameters are for 2D and 3D types, and for 4D types, the drilling parameters should be correspondingly reduced by 15%.

- When the cooling method is only external cooling, the cutting speed should be reduced by 10%.

- For the processing of austenitic stainless steel, internal cooling must be used.

- When starting external drilling on the inclined plane, or when there are pre drilled and intersecting holes in the parts, or when drilling multi-layer plates, the feed rate needs to be reduced to about one-third of therecommended value.

Note

- When using the lathe, it is easy to crush and burn the U-drill when using it with a deviation from the center

- When using small-sized U-drills, high speed and high feed are required, because the lower the parameters, the greater the cutting resistance, and the situation of burning the tool is easy to occur