Description:

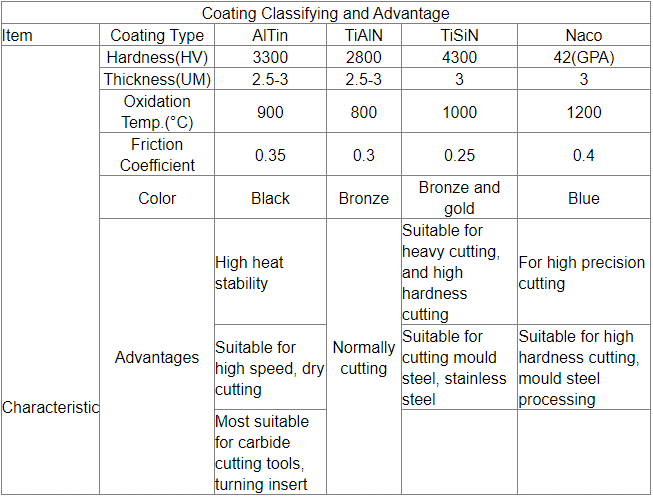

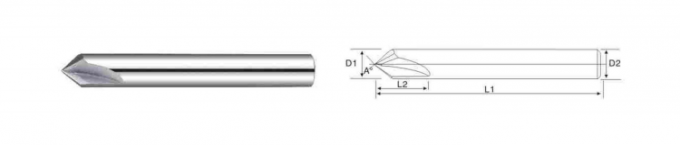

Selected high-quality bar material, high-precision grinding process, reduce vibration, not easy to break the knife, greatly improving the service life of the knife; Unequal spiral and large chip discharge groove design enable fast chip breaking and chip discharge performance, smooth cutting, reduce burrs and not easy to stick the cutter, and achieve high productivity in cutting; High quality coating technology, different series of different coatings, easy to distinguish; Universal chamfered round handle design, easy to use, with good compatibility.

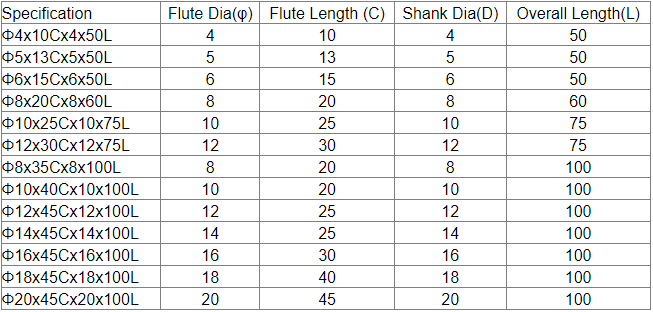

Specifications

Tips:

The above specifications are standard Size, with a large amount of stock. At the same time, we support OEM customized production, the diameter is 0.2mm to 25mm, the Total length is 50mm to 200mm, include inch size end mill , the number of Flute is 4F, 5F, 6F, 8F and the logo could becustomized.

Notice:

- Handle with care to avoid impact damage.

- The loading and unloading of milling cutter should be protected with a rag to prevent hands from being injured or the cutter edge from being damaged by falling

- During milling, the milling cutter shall be fully separated from the working object before starting the machine to avoid damaging the cutter due to impacting the working object

- The shorter the distance between the edge of the milling cutter and the bobbin, the better to reduce the vibration of the milling cutter. The length of the cutter should not be too long

- Select the correct and appropriate end milling cutter to mill the working object, and select the cutting speed and feed according to the material of the working object

- When the cutting data is unclear, the feed rate (feed rate) shall be reduced for testing, and then the processing data shall be gradually corrected to achieve the ideal production effect. Do not make rapid advances to cause damage or injury to the milling cutter.

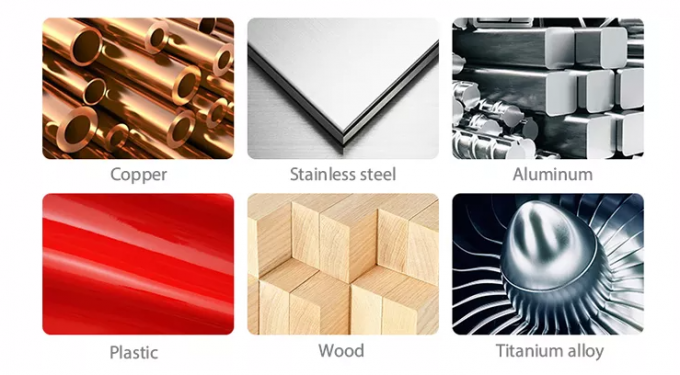

Applications:

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and sO on. General-purpose operation slotting, rilling, profiling.