Description:

- High quality 6542HSS material. Extended tool life and wear resistance

- Full grinding edge design, smooth drilling without residue

- Wide spiral chip removal groove design, smooth chip removal, conducive to medium and high speed machining

- Precision grinding 120 ° double edge rear angle, sharp cutting, high efficiency

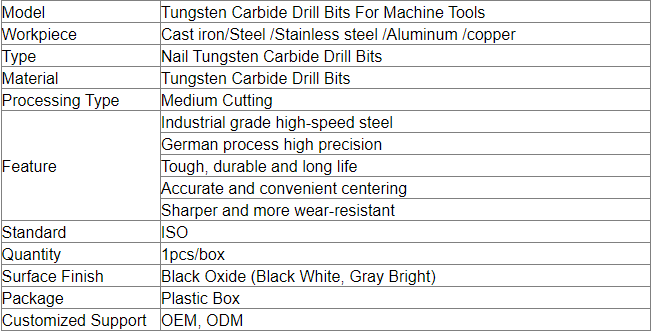

Parameter:

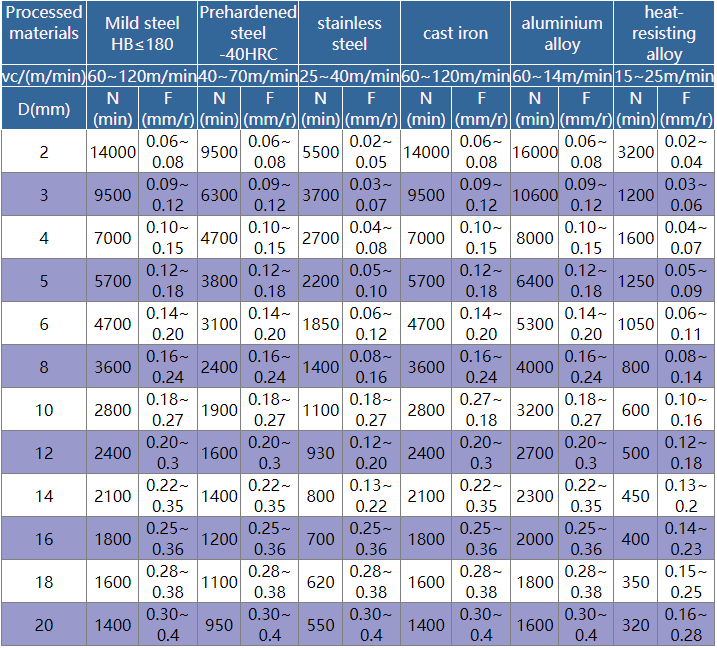

3D/5D External Cooling Cutting Parameters

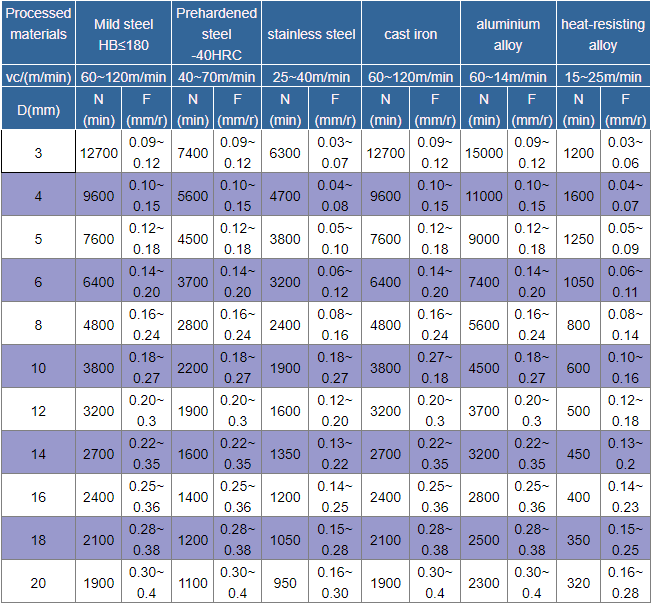

3D/5D internal cooling cutting parameter

- When using this tungsten carbide drill bits for the first time, try to cut at 90% of the cutting speed or 85% of the feed speed according to the above data, and then increase the cutting speed and feed rate one by one after the cutting condition is stable

- This standard cutting condition is applicable to water-soluble cutting fluid

- When installing the tool, please use a clean chuck with defects removed, and control the radial runout of the drill bit within 0.02mm

- The cutting conditions in this table are applicable to situations with hole depth below 5D

Notice:

- Type A central tungsten carbdie drill bits are a cutting tool and is mainly used for metal drilling. Users must reasonably select the type of central drill according to the hole type and ruler size of the parts to be processed

- The hardness of Type A central tungsten carbdie drill bits is 62-64 degrees, which can be used to process steel parts and stainless steel

- Before the tool is used, the anti rust grease must be cleaned to prevent chips from sticking to the blade and affecting the cutting performance

- The surface of the workpiece to be machined shall be straight without sand holes or hard spots to avoid damage to the tool

- Precautions: In case of any abnormal condition during processing, stop processing immediately, find out the cause before processing, and pay attention to the wear of the cutting edge for timely repair; Clean the oil stain on the surface of the tool after use and keep it properly

- This product can be reground for use

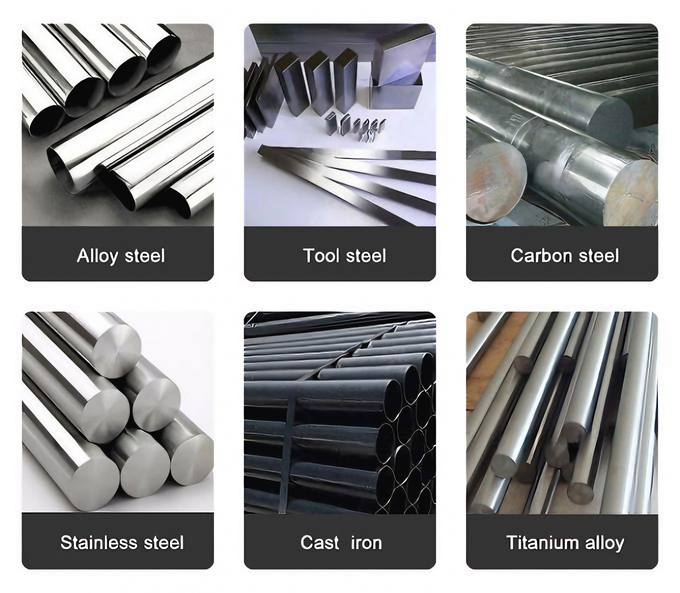

Applications:

Our tungsten carbide drill bits could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following: