Choosing the right end mill is not about finding the most expensive tool or the most aggressive geometry. It is about matching the end mill to your specific manufacturing application. When the tool, material, machine, and process work together, you achieve higher productivity, longer tool life, and more stable machining.

This guide is written for beginners and intermediate users who want to understand how to select end mills based on real manufacturing performance, not just catalog descriptions.

After reading this article, you will understand:

- Why “performance” depends on the application

- How different manufacturing industries use end mills differently

- Which end-mill features matter most for each type of production

- How to make practical selection decisions for consistent results

1. What “Performance” Really Means in Manufacturing

Before choosing an end mill, you must define what performance means for your application. Performance is not the same in every manufacturing environment.

Common Performance Goals

- Longer tool life

- Faster cycle time

- Better surface finish

- Stable and repeatable results

- Lower cost per part

For example:

- A mold shop may prioritize surface finish and accuracy

- An automotive line may prioritize speed and tool life

- A job shop may prioritize flexibility and reliability

There is no “best end mill” — only the best end mill for your application.

2. Start with the Manufacturing Industry

Different industries place very different demands on end mills. Understanding your manufacturing environment helps narrow down the correct tool type immediately.

Typical Manufacturing Categories

- Aerospace

- Automotive

- Mold & Die

- Medical

- General CNC job shops

- Heavy machinery and industrial parts

Each category uses end mills differently.

3. Choosing End Mills for Aerospace Manufacturing

Manufacturing Characteristics

- Lightweight materials (aluminum, titanium)

- Complex geometries

- Tight tolerances

- Long machining cycles

Performance Priorities

- Dimensional accuracy

- Stable cutting

- Heat resistance

- Consistent tool behavior

End Mill Selection Guidelines

- Use solid carbide end mills for rigidity

- Choose variable flute designs to reduce vibration

- For aluminum: fewer flutes, polished flutes

- For titanium: strong core, heat-resistant coatings (TiAlN, AlCrN)

- Prefer shorter tools whenever possible for stability

In aerospace, predictable performance is often more important than maximum speed.

4. Choosing End Mills for Automotive Manufacturing

Manufacturing Characteristics

- High-volume production

- Repetitive operations

- Mixed materials (steel, cast iron, aluminum)

Performance Priorities

- Tool life

- Cycle time

- Cost per part

- Consistency across batches

End Mill Selection Guidelines

- Application-specific end mills outperform general tools

- Roughing end mills for fast material removal

- Durable coatings to handle long production runs

- Consistent diameter tolerance for automated machining

In automotive production, repeatability and durability define performance.

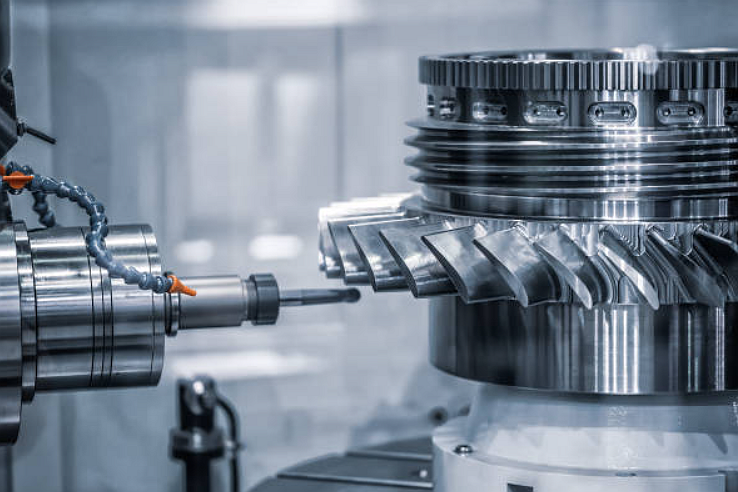

5. Choosing End Mills for Mold & Die Manufacturing

Manufacturing Characteristics

- 3D surfaces

- Deep cavities

- High surface finish requirements

Performance Priorities

- Surface quality

- Tool stability

- Accuracy

End Mill Selection Guidelines

- Ball nose end mills for 3D contouring

- Corner radius end mills to reduce edge chipping

- Smaller step-over for finishing

- Sharp cutting edges and smooth geometry

For mold and die work, performance means precision and finish, not aggressive cutting.

6. Choosing End Mills for Medical Manufacturing

Manufacturing Characteristics

- Small parts

- Tight tolerances

- Difficult materials (stainless steel, titanium)

Performance Priorities

- Accuracy

- Clean surface finish

- Minimal burrs

End Mill Selection Guidelines

- Micro or small-diameter carbide end mills

- High-precision grinding tolerances

- Stable flute geometry

- Coatings that reduce heat and wear

In medical manufacturing, control and reliability are critical.

7. Choosing End Mills for General CNC Job Shops

Manufacturing Characteristics

- Wide variety of materials

- Short production runs

- Frequent tool changes

Performance Priorities

- Versatility

- Reliability

- Ease of use

End Mill Selection Guidelines

- General-purpose carbide end mills

- Balanced flute counts (3–4 flutes)

- Standard lengths

- Tools suitable for multiple materials

Job shops benefit from flexible tools that perform well in many situations.

8. Match the End Mill to the Workpiece Material

Material selection is one of the biggest factors in end-mill performance.

Aluminum

- Soft, sticky material

- Requires sharp edges and chip space

Best choices:

- 2 or 3 flutes

- Polished flutes

- Uncoated or DLC coated

Steel

- Strong and abrasive

Best choices:

- 4 or more flutes

- Strong cutting edges

- TiAlN or AlCrN coatings

Stainless Steel

- Tough and work-hardening

Best choices:

- Sharp but strong geometry

- Reduced vibration designs

- Heat-resistant coatings

Matching geometry to material directly improves performance.

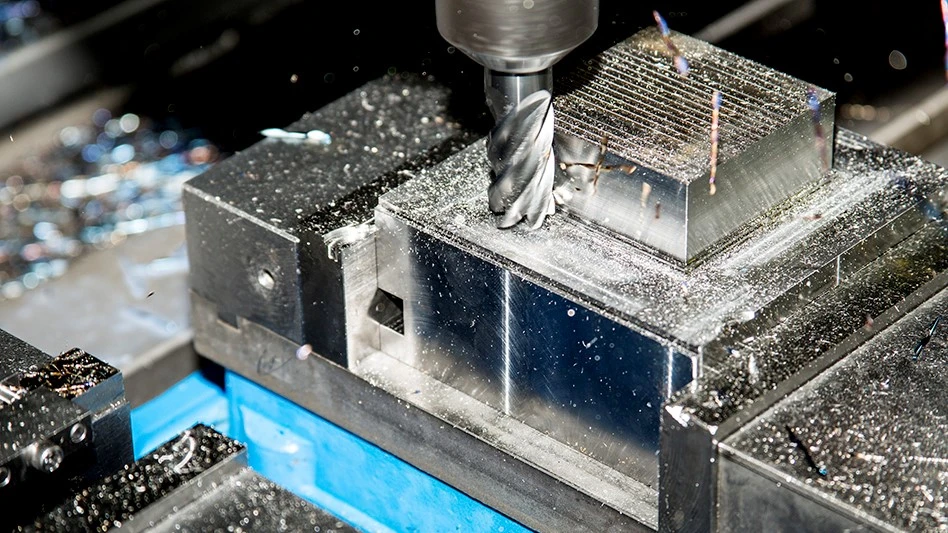

9. Choose the Right End Mill Shape

The shape defines what the tool can do efficiently.

Square End Mills

- Slotting

- Pocketing

- General machining

Ball Nose End Mills

- 3D contouring

- Mold surfaces

- Curved profiles

Corner Radius End Mills

- Improved tool life

- Semi-finishing and finishing

Choosing the wrong shape often leads to poor results even with correct speeds and feeds.

10. Flute Count and Its Impact on Performance

Flutes affect both strength and chip evacuation.

Fewer Flutes

- Better chip removal

- Suitable for soft materials

More Flutes

- Stronger cutting edges

- Better for harder materials

Variable Flutes

- Reduced chatter

- Smoother cutting

Flute selection should always reflect material and cutting strategy.

11. Tool Length and Rigidity

Longer tools are not better — they are weaker.

Performance Impact

- Longer tools increase vibration

- Shorter tools allow higher cutting parameters

Best Practice

Always choose the shortest tool that can reach the machining area. This simple rule improves performance in almost every application.

12. Coatings and Their Role in Performance

Coatings protect the tool and control heat.

When Coatings Matter Most

- High-speed machining

- Hard materials

- Long production runs

Common Coating Functions

- Reduce friction

- Improve heat resistance

- Extend tool life

Using the wrong coating can reduce performance instead of improving it.

13. Machine Capability Must Match the Tool

Even the best end mill cannot perform well on an unsuitable machine.

Important Machine Factors

- Spindle speed

- Rigidity

- Tool holder quality

- Coolant system

If your machine is less rigid, choose:

- Fewer flutes

- Stronger geometry

- Conservative cutting parameters

Tool selection should always consider machine limitations.

14. Stock vs Custom End Mills for Performance

Stock End Mills

- Fast availability

- Lower cost

- Suitable for common applications

Custom End Mills

- Optimized geometry

- Higher performance in specific tasks

- Lower cost per part in production

Many manufacturers start with stock tools and move to custom tools after process validation.

15. Supplier Support Affects Performance

Performance is not just about the tool itself.

A good supplier provides:

- Clear application recommendations

- Speed and feed guidance

- Consistent quality

- Stable supply

For many manufacturers, strong technical support directly improves machining results.

16. Common Mistakes That Reduce Performance

- Choosing tools based only on price

- Using one tool for all materials

- Selecting long tools unnecessarily

- Ignoring vibration issues

- Skipping application guidance

Avoiding these mistakes often delivers immediate performance improvement.

17. A Simple Performance-Focused Selection Checklist

Before selecting an end mill, ask:

- What industry and application is this for?

- What material am I machining?

- Is this roughing or finishing?

- What shape and flute count are required?

- What tool length is really needed?

- Does the coating match the application?

- Can my machine support this tool?

Final Thoughts

High-performance end milling is not about pushing limits blindly. It is about making smart, application-specific choices.

When you select end mills based on:

- Manufacturing type

- Material

- Operation

- Machine capability

you achieve better tool life, higher productivity, and more predictable results.

If you need help selecting the right end mill for your specific manufacturing application, working with a supplier that understands both tooling and real machining conditions will always lead to better performance.