Your End Mills Purchasing is Easy

We are a one-stop supplier for End Mills solutions. We promise to be there for you if you want to scale your business. We provide exclusive service for your End Mills purchasing in stock or customization.

Quality Guaranteed, No Overpaying.

Benefits to End Mills Customization from Shawn

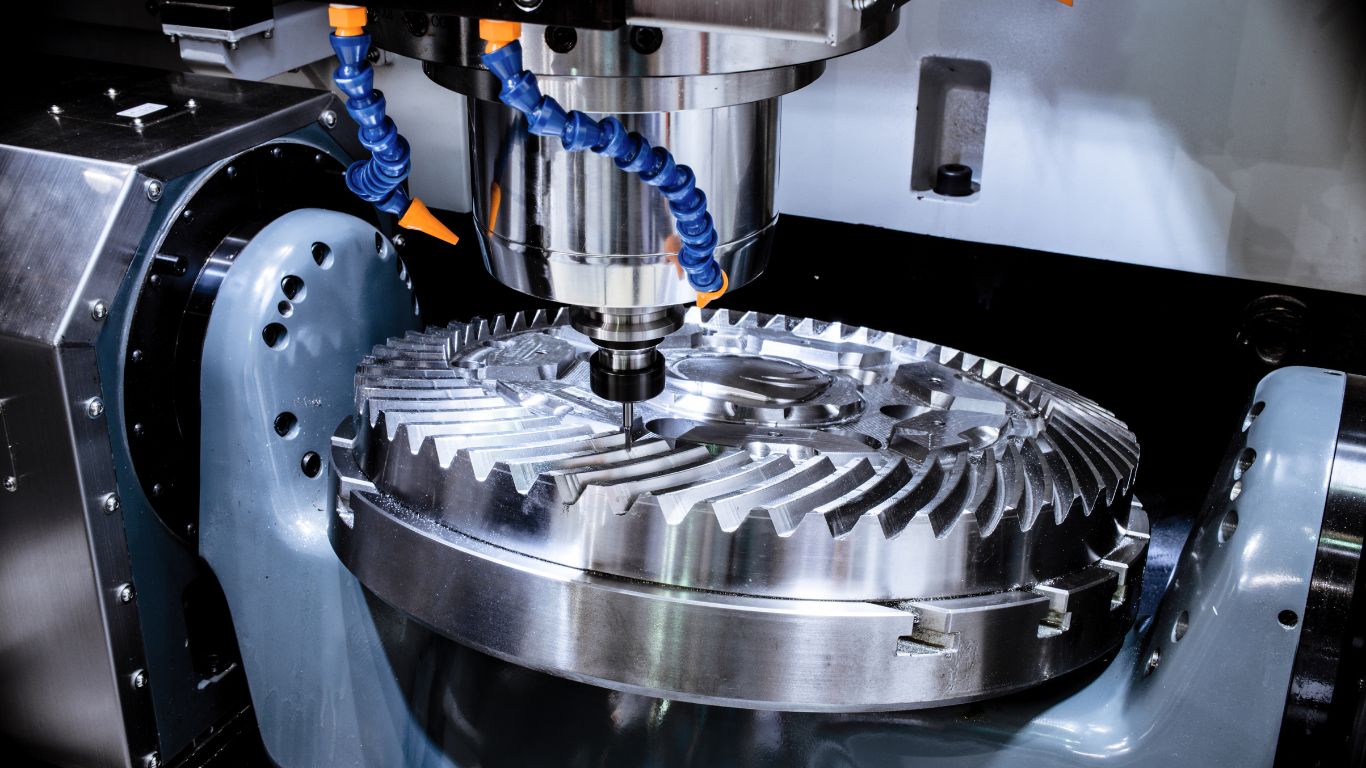

Our wholesale end mills are developed to meet the practical demands of CNC machining in industrial production environments. Designed for performance consistency, durability, and cost efficiency, our products are trusted by distributors and machining professionals across global markets.

Exact Match to Your Machining Application

We customize geometry, flute design, length, and coating to match your specific materials, cutting conditions, and machining goals—helping you achieve optimal performance rather than using generic tools.

Improved Tool Life and Process Stability

Customized end mills reduce vibration, edge chipping, and premature wear, resulting in longer tool life, fewer tool changes, and more stable CNC operations.

Higher Machining Efficiency

By tailoring flute count, helix angle, and cutting edge design, customized tools enable higher feed rates and smoother cutting, improving productivity and reducing cycle time.

Cost Optimization for Your Production

Customization focuses on real cutting needs, helping lower cost per part by reducing scrap, downtime, and unnecessary tool consumption.

Flexible MOQ with Stable Batch Consistency

We support reasonable minimum order quantities while maintaining strict quality control, ensuring consistent performance across repeat orders.

Seamless Transition from Stock to Custom Tools

Customers can start with our in-stock end mills for quick testing and move smoothly to customized versions once applications are validated, minimizing risk and lead time.

Aluminum End Mill

Aluminum end mills are designed specifically for machining aluminum and non-ferrous materials. They typically feature fewer flutes, polished flute surfaces, and sharp cutting edges to ensure smooth chip evacuation and prevent material adhesion. These tools enable high spindle speeds and feed rates while maintaining excellent surface finish. Aluminum end mills are widely used in automotive, aerospace, electronics, and general CNC production where efficiency and surface quality are critical. Selecting the correct aluminum end mill helps reduce built-up edge, extend tool life, and improve overall machining productivity.

Carbide Ball Nose End Mill

Carbide ball nose end mills feature a rounded cutting tip, making them ideal for 3D contouring, profiling, and finishing curved surfaces. Manufactured from solid carbide, they provide high rigidity, wear resistance, and dimensional accuracy. These tools are commonly used in mold and die making, aerospace components, and complex part machining. Ball nose end mills are especially effective for finishing operations where smooth surface transitions are required. Proper selection of diameter, flute count, and coating ensures stable cutting performance and consistent surface quality in demanding applications.

Carbide Milling Cutter

Carbide milling cutters are versatile cutting tools used for a wide range of milling operations, including face milling, side milling, slotting, and profiling. Made from solid carbide, they offer excellent hardness, heat resistance, and long tool life compared to HSS tools. Carbide milling cutters are suitable for machining steel, stainless steel, cast iron, and non-ferrous materials. Their stability and durability make them ideal for high-speed CNC machining and continuous production environments. Choosing the correct geometry and coating helps optimize cutting efficiency and cost per part.

Carbide Square End Mills

Carbide square end mills have a flat cutting bottom with sharp corners, making them one of the most commonly used milling tools. They are ideal for slotting, pocketing, facing, and general-purpose machining. Solid carbide construction provides rigidity and wear resistance, ensuring consistent performance in steel, stainless steel, and aluminum. Square end mills are widely used in CNC production due to their versatility and precision. Selecting the appropriate flute count, cutting length, and coating allows these tools to handle both roughing and finishing operations effectively.

Chamfer End Mill

Chamfer end mills are designed to create beveled edges, deburr sharp corners, and prepare parts for assembly or finishing. They are commonly used to produce precise chamfers at specific angles, such as 45° or 60°. These tools improve part safety, appearance, and fit while reducing manual deburring. Chamfer end mills are widely applied in mold making, automotive components, and precision machining. Proper selection ensures clean edges, consistent chamfer size, and efficient processing in both CNC and manual milling operations.

Corner Radius End Mill

Corner radius end mills feature a small radius at the cutting corner instead of a sharp edge. This design increases tool strength, reduces edge chipping, and extends tool life compared to square end mills. They are commonly used in high-load machining, mold and die work, and applications requiring improved surface integrity. Corner radius end mills help reduce stress concentration on machined parts while maintaining accurate geometry. They are an excellent choice for customers seeking a balance between durability, surface finish, and dimensional stability.

Flat End Mill

Flat end mills, also known as square end mills, are used for creating flat surfaces, slots, and straight walls. They provide precise bottom cutting and sharp corner definition, making them suitable for general CNC milling tasks. Flat end mills are available in various materials, flute counts, and coatings to match different machining needs. They are widely used across industries such as automotive, machinery, and tooling. Choosing the right flat end mill ensures accurate machining results, stable cutting performance, and efficient material removal.

Thread End Mill

Thread end mills are used to machine internal and external threads through milling rather than tapping. They provide greater flexibility, allowing one tool to cut multiple thread sizes with high accuracy. Thread end mills produce clean, precise threads and are suitable for blind holes and hard materials. They are commonly used in aerospace, medical, and precision machining industries. Compared to taps, thread end mills reduce breakage risk and enable better control over thread quality, making them ideal for high-value components.

Roughing End Mill

Roughing end mills are designed for rapid material removal in heavy cutting applications. They feature serrated cutting edges that break chips into smaller pieces, reducing cutting forces and vibration. These tools are ideal for rough machining operations before finishing passes. Roughing end mills are commonly used in steel and alloy machining where productivity is a priority. By allowing higher feed rates and deeper cuts, they significantly reduce machining time while maintaining tool stability and improving overall production efficiency.

Frequently Asked Questions

We have compiled the most frequently asked questions about our fiber distribution boxes here for your convenience, but please feel free to contact us if you have any additional questions.

How Can I Get Technical Assistance?

You can contact us for help with:

- Choosing the right end mill for your application (standard, micro, chamfer, profile, runner cutter, etc.)

- Selecting the correct tool material (carbide, HSS, cobalt, or special materials)

- Setting proper cutting speeds and feed rates

- Choosing the right coating for your workpiece material

- Any general questions about machining or tooling

You can call us directly or contact us by email. Our technical team will guide you step by step, even if you are a beginner.

How Do I Find Speed and Feed Information?

We provide speed and feed recommendations for our end mills to help you get started quickly and safely.

These guidelines include:

- Recommended RPM values

- Feed rates for common materials

- Reference tables to simplify CNC programming

If you are unsure, our technical team can help you adjust parameters for your specific machine and application.

Where Are Your End Mills Manufactured?

All of our end mills are manufactured in the China.

We source our raw materials from China. suppliers and work closely with local partners and vendors.

Our main production facilities are located in dongguan, guangzhou, China.

We supply end mills to customers across the China and to many countries worldwide.

Do You Offer Resharpening or Recoating Services?

Yes. We offer:

- Resharpening

- Regrinding

- Reconditioning

- Recoating

These services are available for our own end mills and for cutting tools from most other manufacturers. This helps customers extend tool life and reduce tooling costs.

Are Your End Mills CNC Manufactured?

Yes. All of our carbide and high-speed steel end mills are produced using advanced CNC grinding machines.

This allows us to maintain:

- High dimensional accuracy

- Tight tolerances

- Consistent tool performance

Because of this precision, our tools are trusted by aerospace, medical, and defense manufacturing customers.

Do You Ship Internationally?

Yes. We ship end mills worldwide.

We support customers in many countries and help them improve machining quality, productivity, and cycle time through reliable tooling and technical support.

What are your payment terms?

For normal orders, we accept T/T in advance, sometimes for small orders, we accept PayPal. We can not accept payment via credit card for now.